Production of Fischer Tropsch liquids

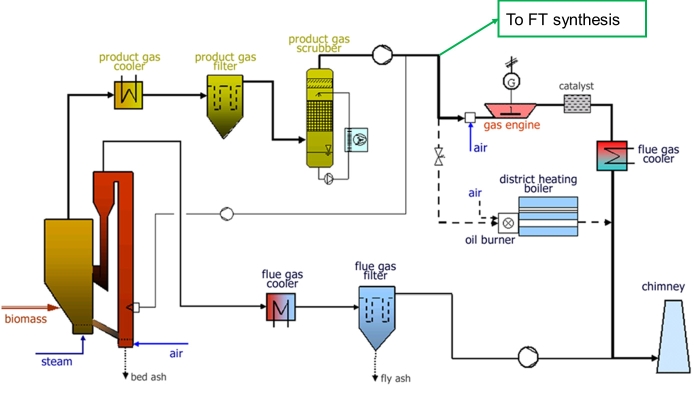

In cooperation with the biomass CHP in Guessing the first biomass-based

Fischer-Tropsch trial plant in Austria was realized in Guessing by Vienna

University of Technology (TUV) in the frame of the EC-project Renew and several national projects in 2005. A new

laboratory scale Fischer-Tropsch-Reactor (slurry reactor) in a side stream of

the existing allothermal fluidised bed gasifier at

BKG was designed and installed. The new FT-synthesis

plant operates in commercial environment and under permanent operation

conditions. By this the long term performance and

behaviour can be investigated. The catalysts used in the FT-slurry reactor are

pre-commercial FT-catalyst, but also research FT-catalysts are studied.

since 2004 now R&D is done on this

synthesis by Bioenergy2020+ together with his scientific partner Vienna

University of Technology. Here a gas treatment and a slurry FT reactor were developed, so that in combination with the steam

gasification, an economic production of FT raw product can be done.

The technical steps are

gasification, gas cleaning and treatment, the FT synthesis itself and the

Hydroprocessing of the raw FT products, as shown in Figure below

In the gasifier, the solid

feedstock is converted into synthesis gas, which

consist mainly of hydrogen and carbon monoxide. In the next step all impurities

like sulfur or chlorine components are removed and in

the gas conditioning, the correct pressure and H2:CO

ratio are adjusted. In the FT synthesis reactor, H2 and CO react on the

catalyst to a mixture of hydrocarbons, mainly paraffin's

with carbon numbers from C1 to C60. The raw product from the FT synthesis

consists mainly of waxes, but also here already a diesel fraction can be separated by vacuum distillation. The wax fraction is finally converted by hydroprocessing, which is a typical

refining process, into diesel and kerosene.

So 2

different types of fuels are produced in a FT synthesis:

- FT-fuels: are the product from the distillation of the FT raw

product and consists mainly of n-paraffins. FT-fuels have excellent properties as diesel additive, e.g. cetane number of 80, only the cold behaviour is not

optimal.

- HPFT-fuels:

are the product from the hydroprocessing of the FT waxes and their

chemical composition can be adjusted in the

hydroprocessing (mainly ratio between n- and iso-paraffins).

High share of iso-paraffins give an excellent

cold behaviour, so by hydroprocessing also kerosene can

be produced.

Both products from the FT

synthesis produce very high quality blending component for fossil diesel or

kerosene. For this reason not only the biomass conversion to FT products, but

also a cooperation with a refinery/fuel distributor is recomended

on the long term, where the refinery makes the final hydroprocessing, the

blending and also the distribution to the consumer.

Description of the FT plant

At the location of Güssing a lab-scale plant for the conversion of

5Nm³/h of product gas is available. On this lab-scale plant first a

reliable gas treatment to remove catalyst poisons and afterwards the slurry FT

reactor itself was developed. This lab scale plant

uses the synthesis gas from the biomass CHP Güssing after removal of

particles and heavy tars, as shown in the figure below.

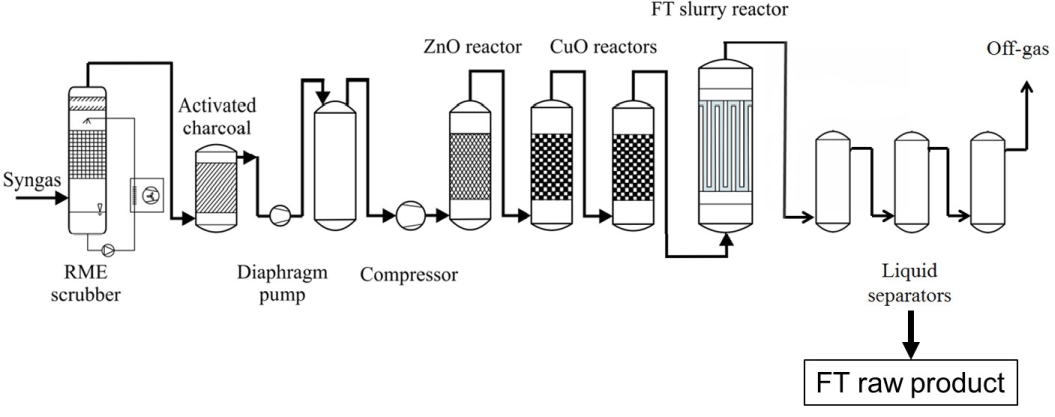

The flow chart below shows the test rig for the Fischer Tropsch synthesis. The FT synthesis consists of the following main parts:

- Gas drying by biodiesel scrubber

- 1st

gas cleaning by activated charcoal

- Compression

of the gas to 20-30 bar

- 2nd

gas cleaning by various adsorbers (ZnO, CuO, NaAlO 2 )

- slurry FT reactor

- separation

of FT raw product from tailgas

During the experiments different combinations of the gas cleaning

devices, different catalysts and operation parameters were tested.

The first step of drying is

necessary, because the product gas has a water content of about 10%, which

would condense in the gas compressions step. Here the gas is

cooled down to about 3°C in direct contact with biodiesel, to remove

the water content of the product gas. The second step of activated charcoal

removes the main amount of sulphur and other poisons (also to protect the gas

compressor). The compression of the gas consists of two steps, first a

diaphragm pump to about 5 bars and then a piston

compressor to 20-30 bars. The second gas cleaning consists of different adsorbers like ZnO or CuO to remove all catalyst poisons to below 10bbp.

After the gas treatment the clean gas is heated up to about 250°C and

fed into the FT-reactor. The Fischer Tropsch reaction takes place in a slurry

reactor (three phases; catalyst, gas, waxes) with a volume of 20 liters. The gas is leaving the reactor over sintered metal

filters. After the FT-reactor the Ft product together

with the tailgas is cooled down in several steps to

room temperature. Here the condenssation and

separation of the raw FT product takes place.

The liquid FT products are collected and distilled. The fraction up to 180°C is used as naphtha, from 180°C to 320°C is as diesel

and the fraction above 320°C are waxes. The

different liquid FT-products are delivered to the

partners in different projects.